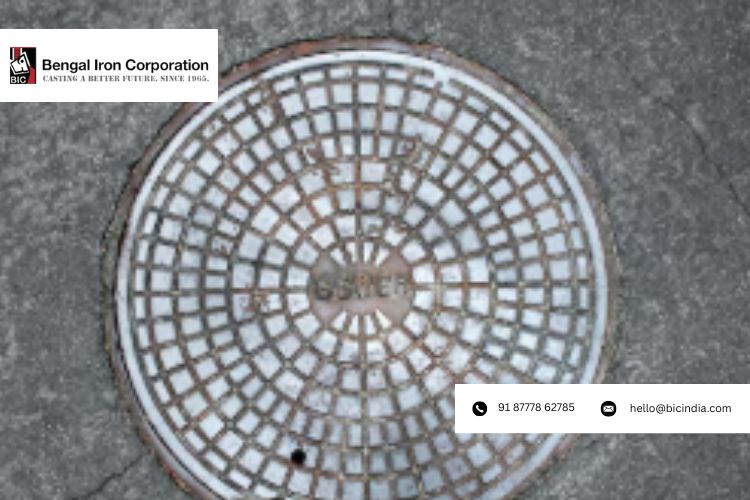

When heavy traffic and harsh weather batter your infrastructure, material choice matters. Municipal engineers and industrial planners alike know that quality Cast Iron Drainage Covers consistently outperform lighter alternatives, keeping streets, factories, and commercial complexes safe year after year.

The Timeless Strength of Cast Iron

There’s a reason cast iron has been used in drainage systems for centuries. The material’s high carbon content creates a dense, wear-resistant structure that laughs off constant wheel loads. According to the U.S. Department of Transportation (source), properly maintained cast iron infrastructure can last over 75 years—sometimes a full century—before significant replacement is needed.

Why Cast Iron Outlasts Other Options

Competing materials like plastic composites or lightweight concrete have their place, but for B2B buyers focused on total lifecycle costs, cast iron’s advantages stack up quickly:

- Extreme Load Capacity: Ideal for highways, freight yards, and airport runways where trucks and heavy equipment are routine.

- Corrosion Resistance: With modern coatings, cast iron shrugs off moisture and chemical exposure better than many metals.

- Thermal Stability: Unlike polymer covers, cast iron won’t warp or degrade in scorching sun or freezing winters.

Key Features B2B Buyers Value

- Precision Casting: Smooth seating surfaces reduce vibration and prevent dislodgment, lowering maintenance calls.

- Security Designs: Locking systems deter theft, a growing concern in urban environments.

- Custom Branding: Municipalities and private parks increasingly request embossed logos for quick identification and aesthetic appeal.

Sustainability and Modern Manufacturing

Today’s foundries aren’t stuck in the past. Leading producers integrate recycled scrap into their melts and capture emissions to meet stringent environmental rules. Many B2B buyers also source from certified plants such as a reputable Ductile Iron Foundry India, ensuring each cover combines old-world durability with modern eco-standards. Ductile iron, with its added nodularity, even enhances impact resistance without sacrificing the traditional heft customers expect.

Real-World Applications

From ports and airports to food-processing plants, cast iron drain covers quietly carry enormous responsibility. A few typical B2B use cases:

- Municipal stormwater networks enduring decades of vehicle traffic.

- Industrial campuses where chemical runoff demands extra corrosion protection.

- Heavy-duty logistics hubs that require proven load ratings and tamper-resistant locking systems.

Practical Buying Tips

Before issuing your next purchase order, consider these expert recommendations:

- Request third-party load-test certificates to confirm EN 124 or equivalent standards.

- Inspect machining tolerances—tight fits reduce rattling and prolong surrounding concrete life.

- Ask about recyclability; many suppliers offer buy-back programs for end-of-life covers.

And if your project includes underground pipelines, a trusted Cast iron pipe Supplier can provide compatible fittings, ensuring consistent material performance across the entire drainage network.

FAQs

How long can a cast iron drain cover last?

With proper installation and maintenance, service life often exceeds 75 years, according to infrastructure studies from transportation agencies.

Are cast iron covers cost-effective for large projects?

Yes. While the upfront price is higher than composites, reduced replacement frequency and lower maintenance yield a lower total cost of ownership.

Can these covers handle chemical exposure?

Modern protective coatings and high-grade alloys make them highly resistant to most industrial chemicals and de-icing salts.

Is ductile iron different from standard cast iron?

Ductile iron incorporates nodular graphite, giving it superior impact resistance and flexibility while retaining classic cast iron durability.

Also Read: How to Reduce Flooding Risks with Advanced Manhole Cover Designs

Final Thoughts

For B2B buyers focused on reliability and long-term value, cast iron drain covers remain the benchmark. Their unmatched strength, low lifetime cost, and proven sustainability record make them the go-to choice for demanding infrastructure projects worldwide.

Blog Development Credits:

This blog was envisioned by Soma Maiti, crafted with insights from advanced AI platforms including ChatGPT, Google Gemini, and Copilot, and then meticulously optimized for SEO by Digital Piloto Private Limited.